|

| October 09, 2012 | Volume 08 Issue 38 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

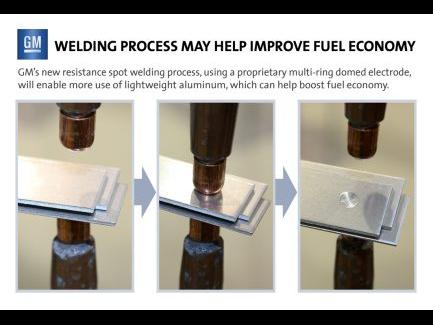

GM welding breakthrough enables more use of aluminum

General Motors Research & Development says that it has invented an industry-first aluminum welding technology expected to enable more use of the lightweight metal on future vehicles, which can help improve fuel economy and driving performance.

GM's new resistance spot welding process uses a patented multi-ring, domed electrode that does what smooth electrodes are unreliable at doing: welding aluminum to aluminum. By using this process, GM expects to eliminate nearly 2 lb of rivets from aluminum body parts such as hoods, liftgates, and doors.

GM already uses this patented process on the hood of the Cadillac CTS-V and the liftgate of the hybrid versions of Chevrolet Tahoe and GMC Yukon. The company plans to use the technology more extensively starting in 2013.

"The ability to weld aluminum body structures and closures in such a robust fashion will give GM a unique manufacturing advantage," says Jon Lauckner, GM chief technology officer and vice president of Global R&D.

"This new technology solves the long-standing problem of spot welding aluminum, which is how all manufacturers have welded steel parts together for decades," Lauckner says. "It is an important step forward that will grow in importance as we increase the use of aluminum in our cars, trucks, and crossovers over the next several years."

Spot welding uses two opposing electrode pincers to compress and fuse pieces of metal together, using an electrical current to create intense heat to form a weld. The process is inexpensive, fast, and reliable, but until now it was not robust for use on aluminum in today's manufacturing environment. GM's new welding technique works on sheet, extruded, and cast aluminum because GM's proprietary multi-ring, domed electrode head disrupts the oxide on aluminum's surface to enable a stronger weld.

Historically, automakers have used self-piercing rivets to join aluminum body parts because of variability in production with conventional resistance spot welding. However, rivets add cost, and riveting guns have a limited range of joint configurations. In addition, end-of-life recycling of aluminum parts containing rivets is more complex.

"No other automaker is spot-welding aluminum body structures to the extent we are planning to, and this technology will allow us to do so at low cost," says Blair Carlson, GM manufacturing systems research lab group manager. "We also intend to consider licensing the technology for non-GM production in automotive, heavy truck, rail, and aerospace applications."

According to Ducker Worldwide, a Michigan-based market research firm, aluminum use in vehicles is expected to double by 2025. The material offers many advantages over steel. One kg of aluminum can replace 2 kg of steel. It is corrosion resistant and offers an excellent blend of strength and low mass that can help improve fuel economy and performance.

According to AluminumTransportation.org, a 5% to 7% fuel savings can be realized for every 10% weight reduction, and substituting lightweight aluminum for a heavier material is one way to do it. Cars made lighter with aluminum also can accelerate faster and brake quicker than their heavier counterparts.

"GM aims to be an industry leader in mass efficiency," says Roger Clark, manager of the GM Energy Center. "Many little things can add up to big improvements in fuel economy. Incremental mass reductions, like using welds instead of rivets, can help our customers save at the pump."

Source: GM

Published October 2012

Rate this article

View our terms of use and privacy policy